Why India Is Becoming a Preferred Hub for Recycled Polyester Yarn

The global textile industry is growing rapidly, but so are concerns around waste, resource depletion, and environmental impact.

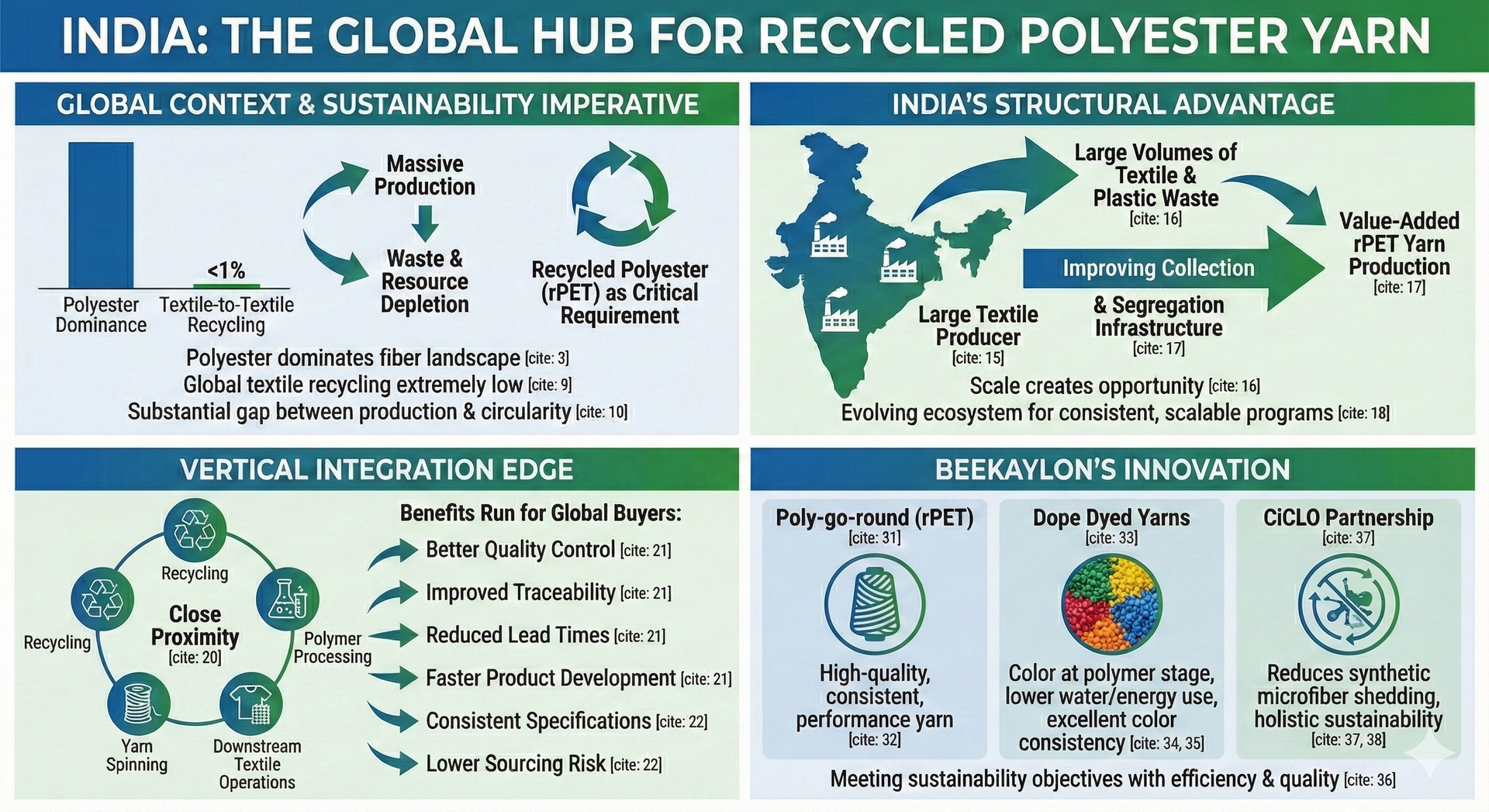

Polyester, known for its versatility, durability, and affordability, dominates the global fibre landscape and accounts for a significant share of overall fibre production. As demand grows, the industry is being compelled to rethink how polyester is produced, sourced, and reused in a more responsible way.

In this context, recycled polyester yarn (rPET yarn) has emerged not merely as a sustainable alternative but as a critical requirement for future-ready textile supply chains. Among major global textile hubs, India is increasingly being recognised as a preferred destination for recycled polyester yarn manufacturing, valued not just for scale, but also for capability, compliance, and long-term reliability.

Global Polyester and the Sustainability Imperative:

Polyester is the most widely used fibre in the world, forming the backbone of apparel, home textiles, and technical fabrics. Despite its dominance, global textile recycling rates remain extremely low, with less than one percent of textiles being recycled back into new textile products. This highlights a substantial gap between production volumes and circular outcomes.

The recycled polyester market, however, has seen consistent growth over the last decade. This growth is being driven by brand commitments, regulatory pressure, and rising awareness around environmental impact. Textile recycling and rPET yarn are no longer peripheral sustainability initiatives but central pillars in the industry’s transition toward circularity.

India’s Structural Advantages in Recycled Polyester Yarn:

India is one of the world’s largest textile-producing nations, with deep-rooted capabilities across fibre production, spinning, fabric manufacturing, processing, and garmenting. This scale naturally generates large volumes of textile and plastic waste, creating both a challenge and an opportunity.

As collection, segregation, and recycling infrastructure improves, increasing amounts of post-consumer PET waste are being channelled into value-added recycled polyester yarn production. India’s evolving recycling ecosystem allows manufacturers to think beyond short-term availability and build more consistent, scalable recycled yarn programmes.

Another key strength lies in India’s vertically integrated manufacturing ecosystem. Recycling, polymer processing, yarn spinning, and downstream textile operations often exist within close proximity. This integration enables better quality control, improved traceability, reduced lead times, and faster product development cycles. For global buyers, this translates into consistent specifications, predictable supply, and lower sourcing risk.

Global Demand and India’s Export Readiness:

International brands are rapidly increasing their use of recycled fibres to meet sustainability and climate targets. Industry frameworks and initiatives encouraging recycled polyester adoption have pushed rPET yarn into the mainstream. While recycled polyester still represents a smaller share of overall polyester production, demand continues to rise steadily.

India’s export-oriented textile industry has decades of experience working with international buyers and compliance standards. As sustainability requirements become more complex, Indian manufacturers have demonstrated increasing capability in meeting expectations around traceability, documentation, and performance consistency.

Beekaylon’s Innovation:

Sustainability today goes beyond recycling alone. Brands increasingly expect materials that combine environmental responsibility with durability, performance, and lifecycle impact reduction.

At Beekaylon, this philosophy is reflected through its recycled polyester yarn offerings under the

Poly-go-round brand. Poly-go-round focuses on delivering high-quality recycled polyester yarns that offer consistency, performance, and suitability across a wide range of textile applications, while supporting circular material flows.

In addition to recycled polyester solutions, Beekaylon brings strong expertise in

Polyester Dope Dyed Yarns. In the dope dyeing process, colour is added at the polymer stage itself, eliminating the need for conventional dyeing at the yarn or fabric level. This results in significantly lower water consumption, reduced energy usage, and minimal chemical discharge, while delivering superior colour consistency, excellent light fastness, and long-term performance.

By offering both recycled polyester yarns through Poly-go-round and a comprehensive range of dope dyed polyester yarns, Beekaylon enables brands and manufacturers to meet sustainability objectives while maintaining efficiency, quality, and design flexibility.

Beekaylon’s partnership with CiCLO further strengthens this approach.

CiCLO is a textile ingredient technology designed to reduce synthetic microfiber shedding during use and at end-of-life, addressing one of the most pressing environmental challenges associated with synthetic textiles. This collaboration reflects a shift toward holistic sustainability rather than isolated interventions.

Challenges and the Road Ahead:

Despite steady progress, recycling rates across the textile industry remain low, and textile-to-textile recycling continues to face technical challenges, particularly with blended fabrics. Additionally, competition from low-cost virgin polyester persists in markets with limited regulatory enforcement.

However, ongoing investment in recycling infrastructure, technology partnerships, and quality systems is helping close these gaps. The convergence of scale, manufacturing capability, and innovation positions India as a long-term and reliable hub for recycled polyester yarn.

Conclusion

India’s emergence as a preferred hub for recycled polyester yarn is driven by integrated manufacturing, improving recycling infrastructure, rising global sustainability demand, and forward-looking innovation. With initiatives such as Poly-go-round and strategic partnerships like CiCLO, companies like Beekaylon are helping shape the future of circular textiles.

For global brands seeking recycled yarn solutions that balance performance, traceability, and sustainability, India is increasingly becoming the sourcing destination of choice.

Sources

- Textile Exchange – Recycled Polyester and Circularity Reports

- Grand View Research – Recycled Polyester Market Analysis

- Fortune Business Insights – Textile Recycling Market

- Fashion for Good – Sorting for Circularity: India

- Down To Earth – Textile Waste and Recycling in India

- ScienceDirect – Polyester Fibre and Sustainability Studies

- Renewable Matter – Textile Recycling and Circular Economy